Great times for hardware startups! Really?

These are amazing times for hardware startups. Companies such as Fitbit, NEST and Beats grew rapidly and went public or recently got acquired by established companies. Hardware startups are benefiting from the increasingly affordable and accessible resources and tools for financing, prototyping, manufacturing, online marketing and sales. This is great news but it doesn’t make “hardware the new software”. Here are some reasons why building a hardware startup is still very different from a software startup:

- you need a large team of designers, engineers and software developers (at least 5 people for a consumer product)

- it costs significantly more than developing software (development costs are at least $200.000 before you are on the market with a typical “smart” hardware product)

- investors won’t give you any money for reasonable conditions without a fully working prototype

- development cycles are long and the number of iterations you can afford is small

- you still need a lot of software development for most products (for many products you need a state-of-the-art companion mobile app on top of the product itself)

- you can’t sell a hardware in “beta” stage to customers and fix it with updates while it’s in use

There are dozens of articles and how-to’s on the Internet going into great detail about these challenges. I guess we read most of them before we decided to quit our jobs in 2014 and put our time and money into developing the world’s first smart design lamp. It has been an amazing roller coaster ride so far and we want to share our experiences and learnings, and the reasons why we still love developing a hardware product.

1. If the founders don’t take care of it, nobody does

Both founders of Luke Roberts are engineers with several years of working experience in management consulting and that helps a lot. We work together with large companies (production and app development), freelancers (product design) and interns (programming). The first lesson we learned: nobody does the thinking for you, not even parts of it. The founders must understand and take care of each and every element of the product they are developing, otherwise it gets really hard and expensive. Outsourcing parts of product development, like large companies do, is nearly impossible for startups because what we are doing has never (exactly) been done before and there is no standardized process for it.

We are just a small fish for large companies and as we have only one shot we ask a lot of questions to understand every detail. This learning is very important, but sales representatives of large companies prefer easier customers with deeper pockets who can afford a budget overrun or a delay. For that reason it is really important to find the right partners that are interested in what you develop and motivated to help you succeed. Working with the best agency or company doesn’t help you if you are their least important customer.

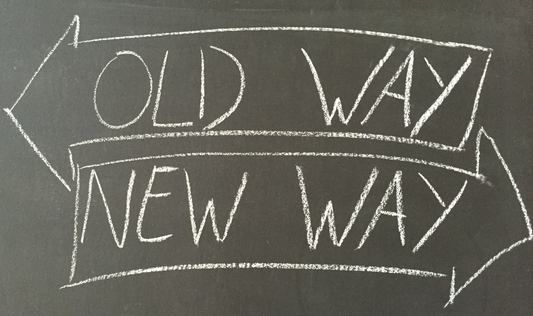

2. If it’s not hard stop doing it

We all came across startup stories like “I had a problem, put a bunch of friends together, developed a first prototype over the weekend with an Arduino and now I am going into mass production.” Nothing is wrong with that, there are great products that are developed this way, especially on crowdfunding platforms. Our approach was different though. We think that if a solution is that easy to build and can be done with $1.000 and 48 hours of work, basically everyone can do it and there is no competitive advantage besides being the first mover. This is fine if you just want to develop a one-off product and don’t worry about competitive advantages or scaling a business. But if you want to establish a company that will grow over time, you better look for a strong market trend (in our case the ban on incandescents and the advent of smart products in our homes), find a weak spot of the current products (in our case the cumbersome remote controls for LED bulbs and poor “smartness”) and develop something that has never been done before (in our case a really smart design lamp).

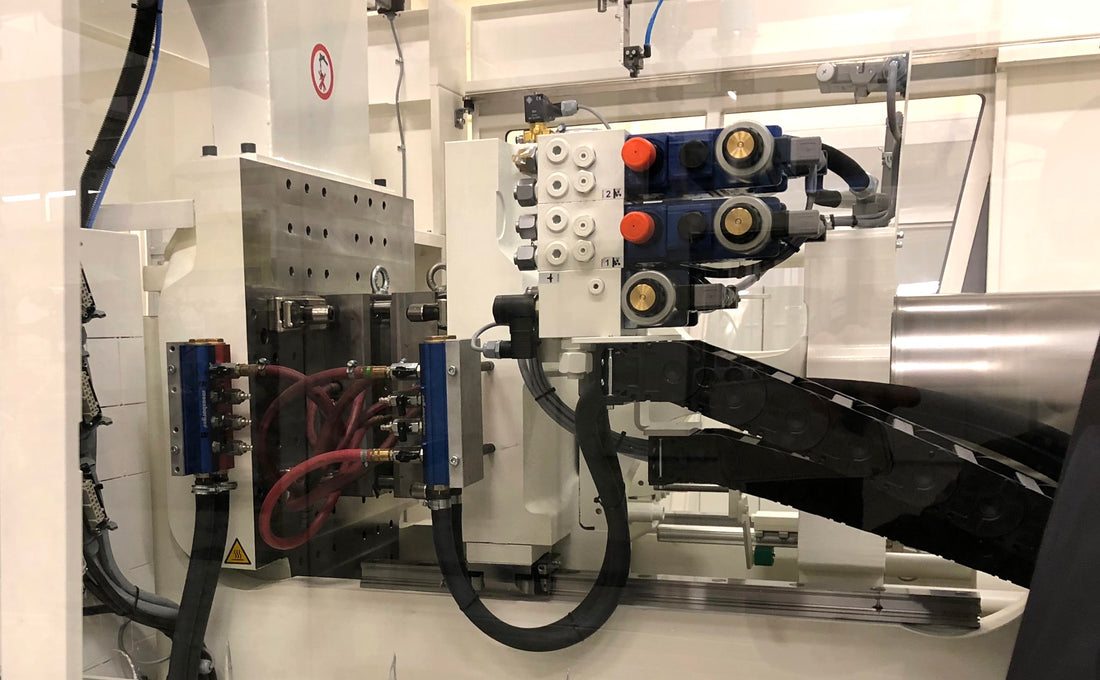

We realized that we are heading in the right direction when we started to talk to production companies and experienced engineers, and all of them told us that they have never done something like that before, but that they really like the product and our approach seems reasonable.

3. The learning curve is steep, very steep

We have worked in academia, large companies and management consulting before founding our hardware startup and the learning curve has never been as steep as it is right now. The beauty (and challenge) of consumer hardware products is that the development involves people from very diverse backgrounds and subject areas. Developing hardware means ensuring that all the different teams deliver their part of the final product at one point in time in the quality and quantity that you need — and there are always “good” reasons for delays.

Compared to a “normal” job, you are responsible and accountable for everything from day one. There is nobody else (your co-founders aside) that feels the urgent need to ensure the success of your product.

Only now, we start to understand why the products around us look the way they do and what degree of complexity companies like Apple are mastering. One more hint: Never ask a manufacturer to produce something in “Apple quality”, it is just not affordable for a start-up to live up to these standards and it makes you look uninformed.

We hope to see many more hardware startups in the near future and wish you all the best if you are already working on something. Don’t hesitate to reach out to us if you have any questions or comments!